Block

General Contracting

General Contracting

P.O. box 2036

Glendale, CA 91209

General Contracting

General Contracting

We are following the researches that have been made in Los Angeles and escort all enforcement which help to depend on renewable resources more than accustomed resources.

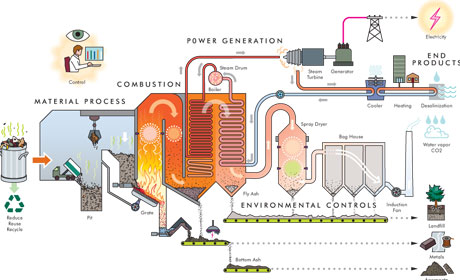

What we are interest to do is recycling more wastes and prevent using more lands to bury trash. This new technology will help to have green world and have clean environment, land, water and air.

Our company has several agreements with different companies and research centers that concern with Waste To Energy (WTE) projects. Most of these companies run WTE projects and eliminate solid waste to generate electrical power.

What is Gasification?

Gasification is a technology that has been widely used in commercial applications for more than 50 years. It's a method to extract energy from materials by converting carbonaceous materials into synthesis gas (syngas). This syngas is itself a fuel or it can be used as a renewable-energy resource. Gasifiers Do Not Incinerate.

Gasifiers operate at 3,000-4,000°F, using a thermo-chemical conversion process that does not include enough O2 for the materials to burn.Instead the materials are broken down at the molecular level and then reformed into reusable products. Our technology does not produce toxic or waste bi-products. Additionally, incineration produces high-levels of CO2, SOx, NOx which are harmful to the environment. Gasification technology does not.

Why Should We Gasify Waste?

Our gasification process is the best solution for waste conversion. Not only can our technology convert 30,000 tons of waste per day in a single unit, it's also versatile and profitable. Additionally, it has a dramatically lower carbon footprint and can be used to create green energy and transportation fuels. In contrast to landfills, which produce enormous amounts of greenhouse gases, leach contaminants into soil and water supplies, and continue to multiply due to increased waste streams. Every ton of waste that is gasified saves the world from the equivalent of more than two tons of greenhouse gases that would be produced in a landfill. Biomass gasification technology converts locally-sourced organic wastes into clean, efficient energy and valuable co-products, with dramatic reductions in CO2 and pollutant emissions.

The durable, flexible system is closely integrated using advanced electronic controls, for optimum efficiency under diverse operating conditions. It also is easily scalable and adaptable to local installations, features low-cost operation and maintenance, and addresses several converging global challenges:

With several systems currently being used to process 48 tons per day of refuse-derived fuel (RDF) sourced from municipal solid waste (MSW) in a full-scale, 24-hour commercial plant, yielding 2 MWH of electricity.

System diagram